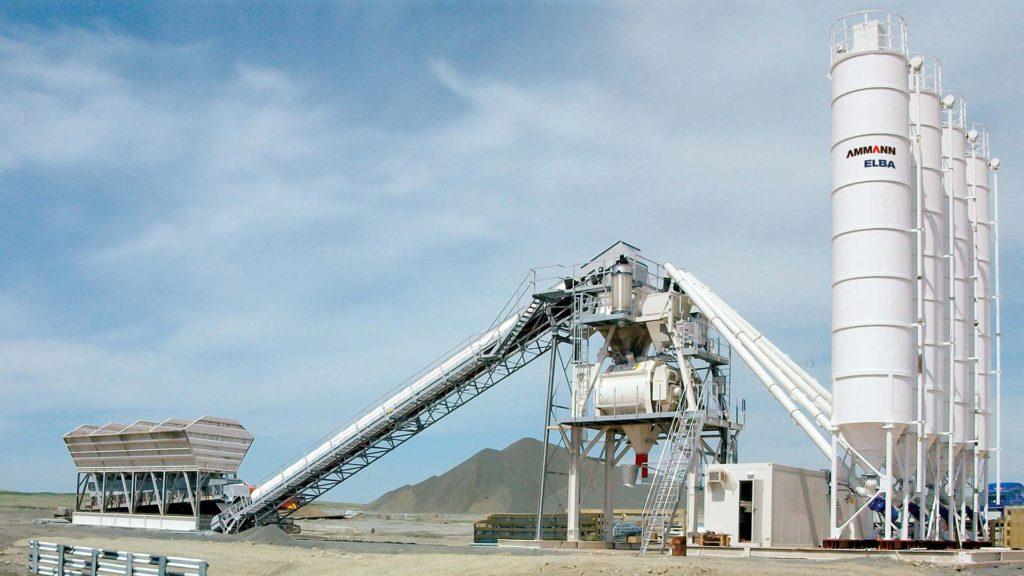

Customers and prospective buyers who are familiar with the benefits of a stationary plant will appreciate the variable options offered by the well-conceived modular principle. Most modern designs that are tailored to the needs of users, are joined together to form a modern plant. A galvanized design of maximum corrosion protection and high-quality components make the CBS Elba to a premium concrete mixing plant.

In the construction of the new concrete plant CBS Elba was great value placed on competitive transportation costs. This was achieved by pre-installed modules.

Large construction sites need high concrete output rates with a reliable, durable and consistant concrete quality. For our high-performance systems CBS 180 TB Elba and CBS 200 TB Elba becomes available.

For standard concrete an hourly output of 177 m³/h up to 190 m³/h are possible.

The twin-shaft mixer CEM T Elba used in these mixing plants is in size 4,0 m³ at CBS 180 TB Elba and 4,5 m³ at CBS 200 TB Elba.

The generously dimensioned walkability facilitate the maintenance and inspection work. The pre-installed weighing module with cement and water weigher and the pre-hopper for aggregates can be completed if necessary with additional required scales as option.

The aggregates, metered in the linear bin are dosed by the conveying belt into the above the mixer placed pre-hopper and emptied via a separate locking directly into the mixer.

The installation of the concrete mixing plant CBS B Elba is made in the basic version on concrete foundation. Optional all CBS B Elba plants can also be erected semi-mobile without foundation.

ZASTÚPENIE ČR a SR

ELTEXIM, s.r.o.BRATISLAVA

tel: +421 33 774 53 35

fax: +421 33 774 53 31

mobil: +421 903 220 097

eltexim@eltexim.sk